Edit Content

- About us

- Products and Services

- Quality & Environment

- NDT Training Centre

- Qualifications & Assessment Centre

- Projects & Tenders

- Info & Media

- Event Reporting

Our specialists have the capability and competence to perform work in the areas listed below, and they periodically benefit from professional training and specialized courses:

The Laboratory Service provides a wide range of services, both in the field of metrological verifications/calibrations within the Metrology Laboratory, as well as in the field of NDT inspections, physico-chemical analyses, and physical–mechanical testing within the Testing Laboratory. Our activity is customer-oriented, with our services meeting both quality requirements and legal and regulatory standards

The activities of the laboratories are accepted and qualified both by customers such as Airbus, Boeing, Bombardier, Safran, GKN and by airline operators among our customers. The Laboratory Service holds AS 9100 certification and SR EN ISO 9001 certification.

The following specialized testing activities are carried out within the Testing Laboratory:

Testing of fuels, lubricants, and hydraulic fluids (contamination level; closed cup flash point, kinematic viscosity, density, water content, chlorine content, acidity, conductivity);

Chemical analyses of the composition of electroplating baths;

Determinations for paints and enamels;

Determination of porosity of electrochemical coatings;

Salt spray corrosion testing;

Filiform corrosion testing;

Analysis of the composition of electrochemical coatings;

Analysis of demineralized water and wastewater.

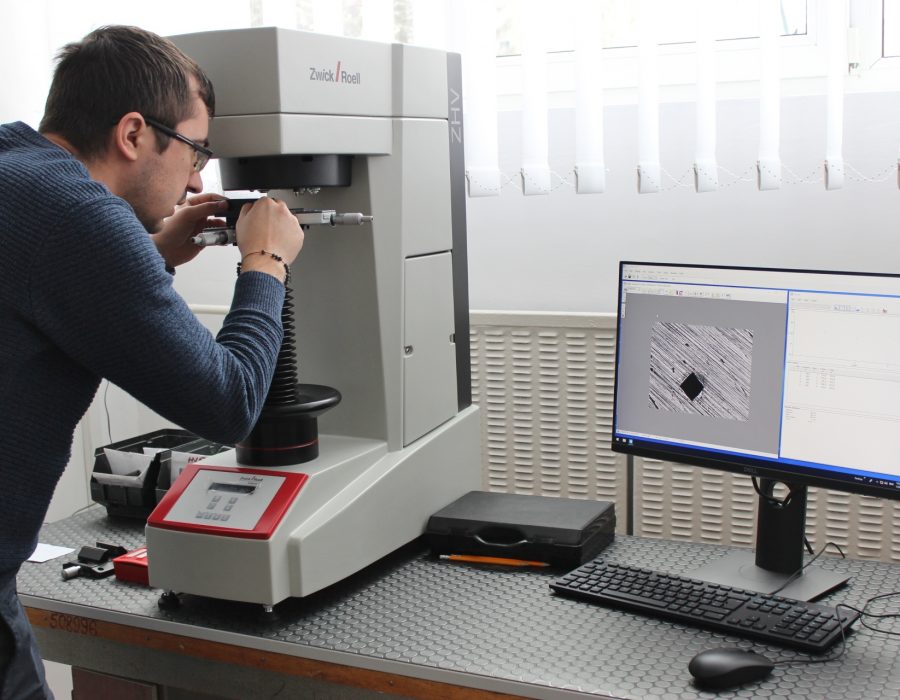

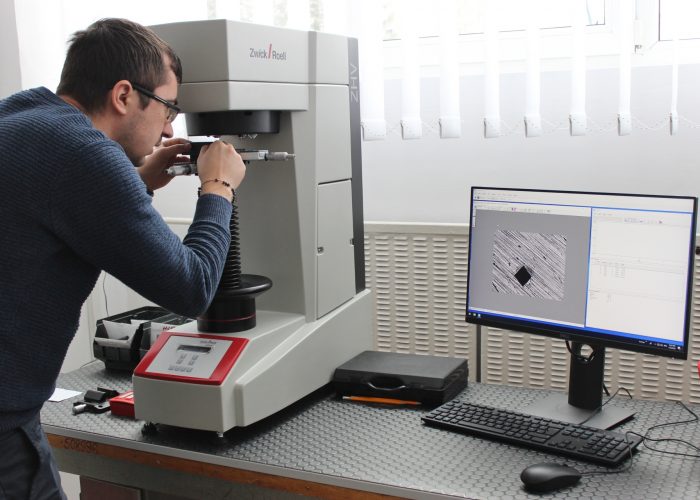

Determination of material characteristics: hardness and conductivity;

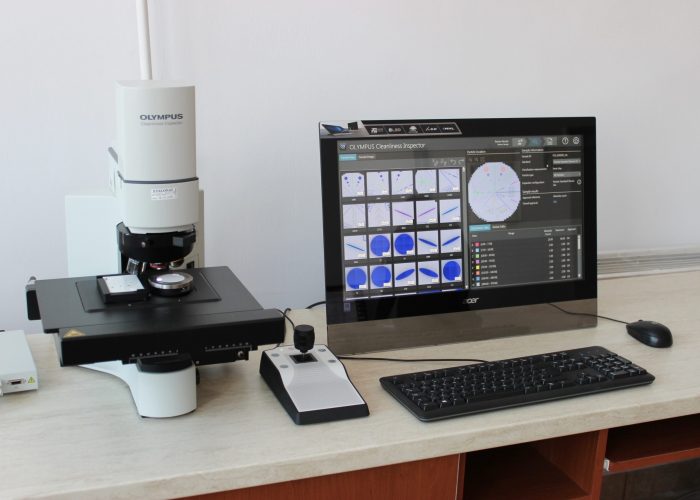

Metallographic analyses;

Testing for: tensile strength, bending, impact bending, and shear;

Within the NDT laboratories, the following are carried out:

The NDT laboratory’s activity is authorized for the D1 category of specialized services – Non-Destructive Testing for the maintenance of civil and military aircraft.

The NDT laboratory is authorized by:

We perform calibrations under RENAR – accredited conditions

in the following fields:

Length

Force

Relative Pressure

Hardness